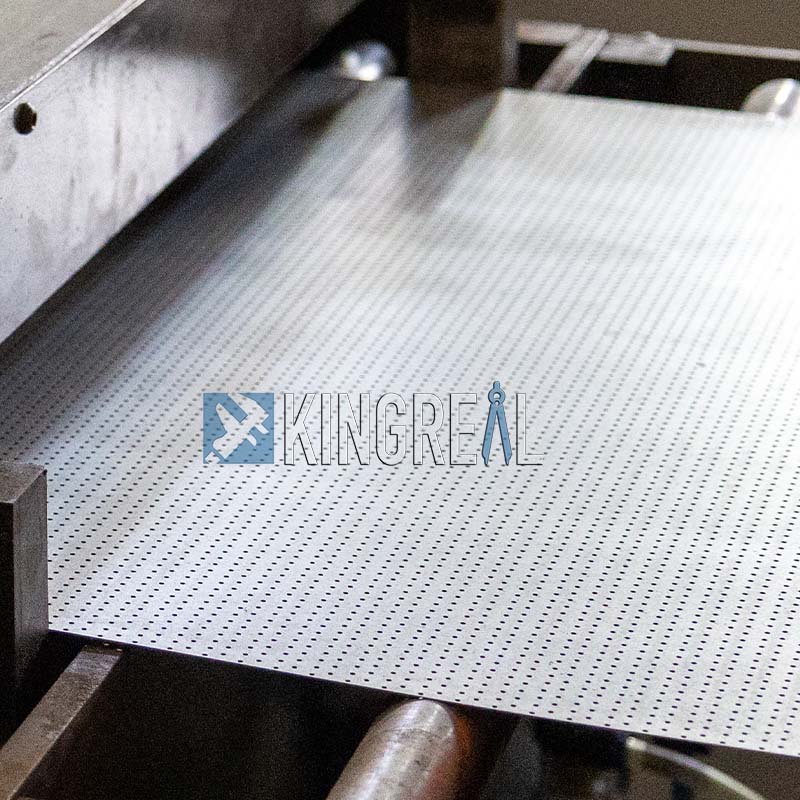

Novo design: Máquina de perfuração de chapa metálica de 700 mm

2025-04-03 17:00

Como empresa líder no setor de linha de perfuração de metal Na área de fabricação de máquinas para tetos, a KINGREAL CEILING MACHINERY sempre se dedicou à pesquisa e desenvolvimento tecnológico e à inovação de produtos. Recentemente, a KINGREAL CEILING MACHINERY lançou uma máquina de perfuração de chapas metálicas de 700 mm. Esta máquina de perfuração de metal não só possui duas funções de processo, corte e rebobinamento, como também pode executar com eficiência tarefas complexas de punção, atendendo amplamente às necessidades dos clientes em termos de flexibilidade e eficiência no processo de produção. Vale ressaltar que esta linha de perfuração metálica pode perfurar furos com diâmetro de até 1,5 mm, o que impõe exigências extremamente altas ao processo de fabricação da matriz de perfuração. Durante o processo de pesquisa e desenvolvimento, a KINGREAL CEILING MACHINERY dedicou especial atenção ao projeto e à seleção de materiais da matriz para garantir sua durabilidade e precisão. Isso torna a linha de perfuração de metal altamente competitiva no campo da estampagem de alta precisão e permite fornecer aos clientes produtos de alta qualidade. |  |

Fundo do projeto da linha de perfuração de metal de 700 mm

O design distomáquina de metal perfuradoBaseia-se nas necessidades reais dos clientes marroquinos. O cliente encontrou a KINGREAL CEILING MACHINERY em uma feira e expressou seu desejo de entrar no mercado de produtos acabados perfurados, além de sugerir a necessidade de uma máquina de perfuração de metal capaz de produzir microperfurações de 1,5 mm. Através de sua pesquisa de mercado, ele identificou painéis de parede perfurados e elementos filtrantes perfurados como os principais produtos que pretende comercializar.

- Painéis de parede perfurados: placas metálicas perfuradas, com linhas de perfuração e cortes, que necessitam de processamento posterior.

- Elementos filtrantes perfurados: bobinas de metal perfurado, finalizadas por máquina de perfuração de metal com rebobinagem, são processadas por um processo secundário.

Na exposição, o cliente marroquino perguntou aos profissionais da KINGREAL CEILING MACHINERY se precisava adquirir duas linhas de perfuração de metal para atender às suas necessidades de produção. Considerando o orçamento de investimento e a eficiência de produção do cliente, os engenheiros da KINGREAL CEILING MACHINERY compreenderam profundamente as necessidades específicas do cliente marroquino e propuseram uma solução inovadora.

Vídeo sobre linha de perfuração de metal

Solução inovadora para máquina de perfuração de chapas metálicas

Após uma análise detalhada da demanda, os engenheiros da KINGREAL CEILING MACHINERY decidiram projetar ummáquina de metal perfuradoque pode atender às duas necessidades de processo do cliente simultaneamente. O conceito de design desta linha de perfuração de metal é alcançar a dupla compatibilidade de processos e fornecer aos clientes um único equipamento para solucionar múltiplas necessidades de produção.

No projeto dos equipamentos, a KINGREAL CEILING MACHINERY considerou os seguintes aspectos:

1. Configuração do equipamento

Os engenheiros da KINGREAL CEILING MACHINERY integraram a estação de corte e a bobinadeira na mesma linha de produção, permitindo que os clientes escolham o processo de acordo com suas necessidades de produção. Esta linha de produção está equipada com uma estação de corte e uma bobinadeira, atendendo às necessidades tanto de corte quanto de bobinamento.

Quer a bobina de metal perfurado precise ser enrolada ou processada na estação de corte, uma única máquina de perfuração de metal pode ser usada para ambas as finalidades.

2. Operação flexível

O design da máquina de perfuração de chapas metálicas permite que os usuários escolham o processo de forma flexível. Quando o cliente precisa realizar o processo de rebobinamento, basta desligar a estação de corte, e a bobina de metal perfurada não será cortada e será enviada diretamente para a rebobinadeira. Por outro lado, quando o corte for necessário, desligue a rebobinadeira e ligue a estação de corte.

Essa flexibilidade não só melhora a eficiência da produção, como também reduz o espaço ocupado pelo equipamento. Além disso, um processo de operação simples e intuitivo foi projetado na interface de controle da linha de perfuração de metal para garantir que até mesmo operadores iniciantes possam começar a utilizá-la rapidamente.

3. Tecnologia de precisão da matriz de estampagem de 1,5 mm

No mercado atual, muitas linhas de perfuração de metal geralmente conseguem atingir aberturas de 1,8 mm e 2,5 mm. No entanto, a KINGREAL CEILING MACHINERY está ciente das necessidades específicas dos clientes marroquinos em relação às aberturas de perfuração e, por isso, personalizou uma matriz de perfuração de 1,5 mm para eles.

Matrizes de puncionamento com aberturas ultrapequenas exigem tecnologias de fabricação mais avançadas. Por isso, no processo de projeto e fabricação desta matriz de 1,5 mm, a KINGREAL CEILING MACHINERY utiliza materiais mais avançados e tecnologia de processamento de precisão, garantindo que ela atenda aos altos padrões de produção exigidos pelos clientes marroquinos.

4. Produção eficiente

Por meio de um fluxo de processo otimizado e configuração de equipamentos adequada, a máquina de perfuração de chapas metálicas de 700 mm pode melhorar significativamente a eficiência da produção, reduzir o ciclo produtivo e garantir a qualidade do produto.

Por fim, a KINGREAL CEILING MACHINERY projetou uma máquina de perfuração de metal para clientes marroquinos, capaz de processar bobinas de metal com 700 mm de largura, e os clientes ficaram muito satisfeitos com essa solução.

Feedback dos clientes marroquinos e resposta do mercado

Os clientes marroquinos imediatamente colocaram o linha de perfuração de metal A máquina entrou em produção após ser recebida. O feedback dos clientes mostra que esta máquina de perfuração de chapas metálicas de 700 mm não só melhora a eficiência da produção, como também reduz os custos de investimento em máquinas de perfuração de metal. Os clientes afirmaram que, ao utilizar essa linha de perfuração de metal, conseguem responder rapidamente à demanda do mercado e ajustar os planos de produção com flexibilidade, destacando-se assim em um mercado altamente competitivo.

Além disso, os clientes marroquinos também afirmaram que os serviços personalizados oferecidos pela KINGREAL CEILING MACHINERY permitem atender melhor às necessidades específicas de cada cliente. Essa flexibilidade e adaptabilidade não apenas aumentam sua competitividade no mercado, mas também abrem novas oportunidades de negócios para eles. |  |

Outros tipos de linha de perfuração de metal

Com o desenvolvimento contínuo da indústria manufatureira global, a demanda de mercado por máquinas de perfuração de metal também está aumentando, apresentando uma tendência de crescimento sem precedentes. Cada vez mais empresas percebem que a capacidade de produção flexível e os processos de produção eficientes são fatores-chave para melhorar a competitividade. Nesse contexto, a linha de perfuração de metal de 700 mm da KINGREAL CEILING MACHINERY não só oferece aos clientes soluções eficientes, como também traz novas oportunidades para todo o setor.

Além da máquina de perfuração de metal de 700 mm, a KINGREAL CEILING MACHINERY também respondeu ativamente à demanda do mercado e projetou diversas linhas inovadoras de perfuração de metal.

Por exemplo, a máquina de perfuração de metal, capaz de produzir microfuros de 1,0 mm, foi projetada para usinagem de precisão e atende à demanda por produtos de alta precisão. Além disso,máquina de perfuração de chapa metálica e cóleolinha de perfuração da bobina também oferecer mais opções aos clientes.

Para cenários de aplicação específicos, a KINGREAL CEILING MACHINERY também lançou umlinha de perfuração do teto metálicoPara atender às exigências duplas da indústria da construção civil, que unem beleza e funcionalidade, essas diversas máquinas para metal perfurado demonstram plenamente a excelência da KINGREAL CEILING MACHINERY em inovação tecnológica e adaptabilidade ao mercado, permitindo que ela mantenha sempre uma posição de liderança em um setor altamente competitivo.

Obter o preço mais recente? Responderemos o mais breve possível (dentro de 12 horas)