Caixa: Máquina de teto de metal

2024-12-17 14:13

Introdução da máquina de teto metálico suspenso

Olinha de produção de teto suspenso de metal é um equipamento automatizado especialmente usado para produzir vários tipos de tetos metálicos suspensos, que são amplamente utilizados na indústria de decoração de edifícios. Telhas metálicas para tetos suspensos se tornaram uma das principais escolhas de materiais modernos de decoração de edifícios devido à sua excelente durabilidade, proteção ambiental, resistência ao fogo e estética. Elas são particularmente adequadas para edifícios comerciais, prédios de escritórios, aeroportos, estações de metrô, hospitais, escolas e outros locais públicos.

A máquina para fabricação de placas de teto suspenso de metal KINGREAL CEILING MACHINERY realiza a produção em massa automatizada de tetos suspensos de metal por meio de uma série de fluxos de processo eficientes e precisos, incluindodesenrolamento, nivelamento, puncionamento, dobra, corte e outras etapas.

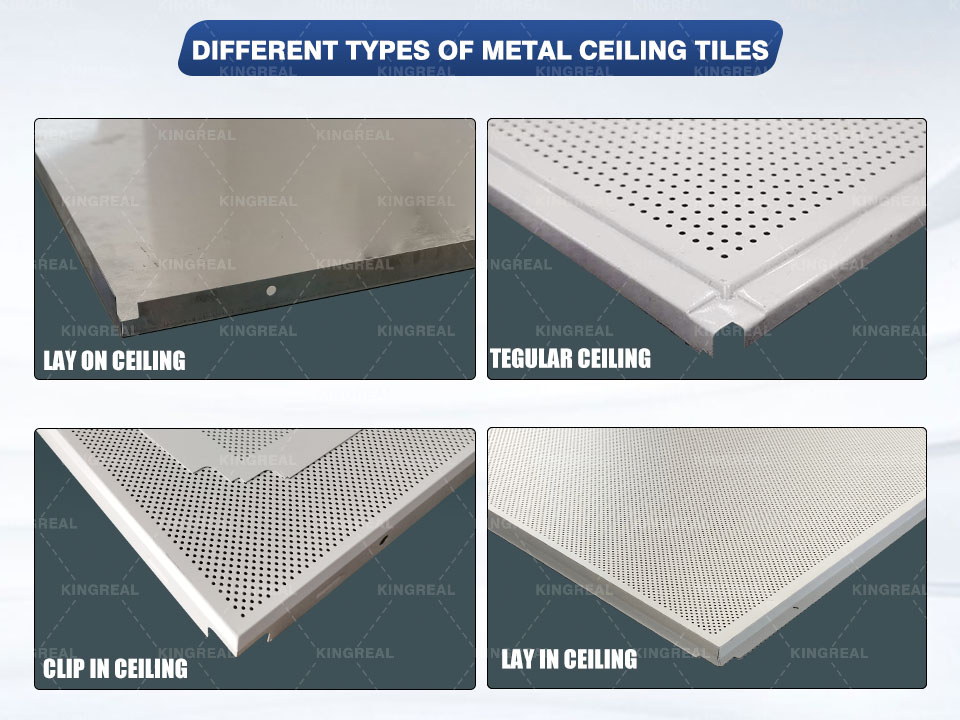

A máquina de teto metálico suspenso KINGREAL CEILING MACHINERY é compatível com uma variedade de materiais metálicos, como liga de alumínio, aço galvanizado, aço inoxidável, e pode personalizar tetos de diferentes especificações, tipos e efeitos de tratamento de superfície de acordo com as necessidades do cliente, comoencaixe,deitado,lado a lado, etc. Os produtos acabados produzidos pela linha de produção de tetos suspensos de metal KINGREAL CEILING MACHINERY não têm apenas aparência plana e tamanho preciso, mas também têm boa resistência à corrosão e propriedades antioxidantes, atendendo às necessidades duplas da decoração de edifícios modernos em termos de beleza e funcionalidade.

Em termos de posição de mercado, as máquinas de teto de metal gradualmente se tornaram equipamentos de produção líderes na indústria com sua alta eficiência, baixo consumo de energia e características inteligentes, e são amplamente favorecidas por empresas nacionais e estrangeiras. Com a crescente demanda por materiais de alta qualidade e ecologicamente corretos na indústria global de decoração de edifícios, a demanda do mercado por tetos suspensos de metal continua a crescer, impulsionando a atualização e inovação contínuas dos equipamentos da linha de produção de teto.

A rica experiência da KINGREAL CEILING MACHINERY

A KINGREAL CEILING MACHINERY é uma fabricante profissional de máquinas para tetos metálicos suspensos que integra P&D, produção e vendas. Ela está profundamente envolvida na indústria há mais de 20 anos, acumulou uma rica experiência e mantém um relacionamento cooperativo próximo com clientes em todo o mundo. A máquina para tetos metálicos suspensos é um dos produtos estrela da KINGREAL CEILING MACHINERY. Com seu excelente desempenho e qualidade confiável, ela ganhou amplo reconhecimento no mercado.

A KINGREAL CEILING MACHINERY tem uma forte equipe de engenheiros, com foco em fornecer aos clientes soluções personalizadas de equipamentos de fabricação de tetos para garantir que o equipamento atenda totalmente às necessidades de produção dos clientes e corresponda com precisão aos cenários de produção reais. Durante o processo de fabricação, a KINGREAL CEILING MACHINERY controla rigorosamente a triagem e a inspeção de qualidade das matérias-primas e verifica em todos os níveis para garantir que cada equipamento seja feito de materiais de alta qualidade para criar uma máquina de teto de metal suspenso de alta qualidade e durável.

Além disso, a KINGREAL CEILING MACHINERY passou pela certificação ISO9000 e tem um sistema completo de gerenciamento de qualidade ISO9000 para garantir processos de produção eficientes e padronizados e qualidade de produto estável e confiável. Com força técnica profissional e padrões de qualidade rigorosos, a KINGREAL CEILING MACHINERY está comprometida em fornecer soluções de máquinas para fabricação de placas de teto suspensas de metal eficientes e de alta qualidade para clientes globais, ajudando os clientes a atingir metas de produção e aumentar a competitividade do mercado.

Casos de sucesso

A máquina de fabricação de placas de teto suspensas de metal da KINGREAL CEILING MACHINERY foi exportada para cerca de 50 países, incluindo Rússia, Coreia do Sul, Alemanha, Espanha e Reino Unido. Abaixo, a KINGREAL CEILING MACHINERY compartilhará três dos casos de sucesso com você.

Máquina para fabricar placas de teto suspensas de metal 30x30 enviada para a fábrica do cliente italiano

Histórico e necessidades do cliente:

O cliente italiano é um fabricante com foco em materiais de decoração de construção de alta qualidade, atendendo principalmente o mercado europeu, e tem requisitos extremamente altos para a eficiência de produção e qualidade do produto final de tetos de metal. O cliente precisa de uma máquina automatizada para fabricação de placas de teto suspensas de metal que possa operar de forma estável e em alta velocidade para produzir tetos de metal de tamanho 30x30 para atender à demanda do mercado por tetos de alta precisão.

Solução:

A KINGREAL CEILING MACHINERY oferece aos clientes umaMáquina de fabricação de placas de teto suspensas de metal 30x30 totalmente automática. O equipamento adota sistemas avançados de controle automatizado para garantir processos de produção eficientes e estáveis. Ao mesmo tempo, os engenheiros da KINGREAL CEILING MACHINERY personalizaram o equipamento de acordo com as necessidades do cliente e otimizaram o controle de precisão e a velocidade de produção do produto final.

Feedback e resultados do cliente:

O cliente italiano disse:"A máquina é rápida, de boa qualidade e funciona perfeitamente."

A linha de produção de tetos suspensos de metal da KINGREAL CEILING MACHINERY atinge uma alta eficiência de 6 folhas de chapas de alumínio por minuto, e a precisão do produto acabado é controlada dentro de ±0,1 mm, o que ajuda os clientes a aumentar rapidamente a capacidade de produção e expandir com sucesso a participação no mercado.

Linha de produção de teto suspenso de metal 60x60 enviada para a fábrica do cliente britânico

Histórico e necessidades do cliente:

O cliente britânico é uma empresa de fabricação de tetos metálicos de longa data que atende edifícios comerciais e grandes projetos públicos. O cliente tem requisitos extremamente rigorosos quanto à precisão de tetos metálicos, enfatizando especialmente que o produto final é livre de rebarbas e tem tamanho preciso para atender aos padrões de qualidade do mercado de ponta.

Solução:

A KINGREAL CEILING MACHINERY oferece aos clientes umaautomatizadolinha de produção de tetos suspensos de metal projetada especificamente para tetos de metal 60x60. O equipamento é equipado com moldes de precisão e sistemas de controle de alta precisão para garantir que os tetos produzidos tenham dimensões precisas, com bordas lisas e sem rebarbas.

Feedback e resultados do cliente:

Clientes britânicos elogiaram muito a linha de produção de tetos suspensos de metal da KINGREAL CEILING MACHINERY:"Os tetos de metal produzidos pelas máquinas de fabricação de placas de teto suspensas de metal da KINGREAL CEILING MACHINERY são altamente precisos e sem rebarbas."

Esta máquina para tetos metálicos não apenas melhora a qualidade do produto, mas também ajuda os clientes a ganhar vários pedidos de projetos de ponta, consolidando ainda mais sua posição no mercado.

Máquina de teto de metal 60x120 enviada para fábrica de cliente mexicana

Histórico e necessidades do cliente:

O cliente mexicano é um conhecido fabricante local de materiais de construção que enfrenta o problema de baixa eficiência de produção. O cliente precisa urgentemente de uma máquina de teto de metal totalmente automatizada para reduzir a dependência de mão de obra, ao mesmo tempo em que melhora a eficiência da produção e atende à crescente demanda do mercado.

Solução:

A KINGREAL CEILING MACHINERY oferece aos clientes umamáquina de teto de metal 60x120 totalmente automatizada, que adota sistemas avançados de alimentação automática, puncionamento, dobra e corte para atingir um alto grau de automação de todo o processo de produção e reduzir significativamente a necessidade de operação manual.

Feedback e resultados do cliente:

Clientes mexicanos disseram:"A máquina de teto de metal totalmente automática libera mão de obra e melhora a eficiência."

A máquina para teto de metal KINGREAL CEILING MACHINERY triplicou a eficiência de produção do cliente, reduziu com sucesso os custos de mão de obra e garantiu a qualidade estável dos produtos acabados, ajudando os clientes a se destacarem na acirrada competição do mercado.

Obter o preço mais recente? Responderemos o mais breve possível (dentro de 12 horas)